|

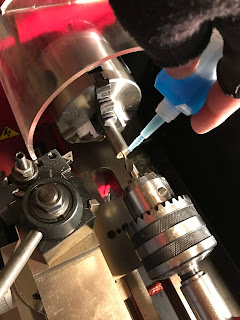

| Before moving to the nickle-silver patches, I practiced the forming process with the molds on softer material, paper and brass. |

|

| Here is the ruff nickle-silver patch I created with the putty moldings. Further shaping was done with jewelers files, 400-600-crocus cloth sandpaper and yellow rouge hand buffing. |

|

| Checking for fit of final patch. |

|

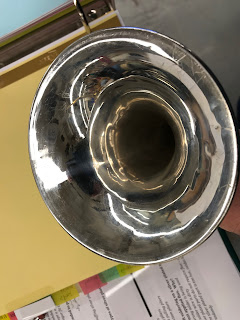

| Here is the completed patch soldered onto the third valve slide crook. I used lead free solder and I plan on matching the patch to the satin finish of the instrument. |

|

| Here is the valve slide placed back on the body of the instrument. Done! |