Again, here is the original fretwork piece in my Mom's house. It depicts the sun, wind, rain and snow.

All things from which a home protects you.

Here I am determining where I will place the oak rounds. To achieve accurate lines so that holes drilled to accept the rounds will line up, I use a square and mark appropriately.

Here I am determining the path of each ray of the sun.

Here I am drilling the holes.

Putting it all together after the holes have been drilled.

All the oak rounds have been cut to fit and the appropriate amount of oak balls have been slid onto each round. Everything fits and now its time to glue it all together.

The staining process.

The drying process.

The finished piece hanging on my living room wall!

I added a bell design I found online and hung it where Mom and Dad hung a cowbell on the original. Somebody or somebodies in the early days of my families ownership of this house kept bumping into the bottom right corner of this archway cracking it in several spots. In order to prevent this from happening, a cowbell was hung at about the same spot as my bell so that visitors would 'steer clear'.

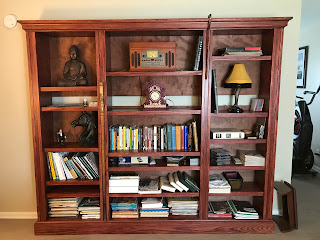

Here it is along with several of my past projects to the left of my fish tank

Here I am determining where I will place the oak rounds. To achieve accurate lines so that holes drilled to accept the rounds will line up, I use a square and mark appropriately.

Here I am determining the path of each ray of the sun.

Here I am drilling the holes.

Putting it all together after the holes have been drilled.

All the oak rounds have been cut to fit and the appropriate amount of oak balls have been slid onto each round. Everything fits and now its time to glue it all together.

The staining process.

The drying process.

The finished piece hanging on my living room wall!

I added a bell design I found online and hung it where Mom and Dad hung a cowbell on the original. Somebody or somebodies in the early days of my families ownership of this house kept bumping into the bottom right corner of this archway cracking it in several spots. In order to prevent this from happening, a cowbell was hung at about the same spot as my bell so that visitors would 'steer clear'.

Here it is along with several of my past projects to the left of my fish tank